Share

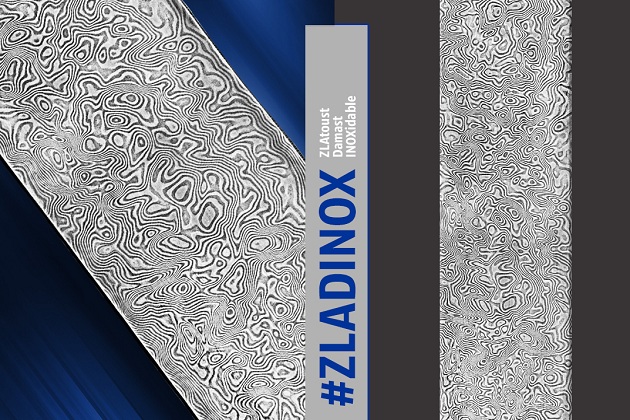

For the convenience of working with Zladinox composite styles, blanks are provided with recommendations for heat treatment and chemical etching (pattern detection).

Specifications of high-carbon compounded steel ZD-0805 (7ХНМ-Х6ВФ)

Designation: for manufacturing blades of knives with high cutting and working properties.

Type of delivery: band or square according to the dimensions of the customer.

Hardness of steel after thermal treatment

| State on delivery, cycles of heating | HRC (НВ) |

|

Annealing: beating from v< 30 degress/hour to 840 C°, cooling with furnace from i<30 degress/hour to 500-600 C°, air. |

187-228 |

|

Heat treatments: 900-940 C°, oil. Tempering 150-180 C°. 1,5 hour, air. |

- |

|

Isothermal quenching: 830-850 C°, molten salt 320-330 C°. Tempering 330 C°. 1,5 hour, air. |

58-62 |

Technological properties

The temperature of forging, C°: beginning 1100, finish 800.

Composition and cycle of etching

5% solution of nitric acid in water for 5-10 minutes, followed by neutralization in a 10% solution of soda ash in water.5% solution of nitric acid for 5-10 minutes, followed by neutralization in a 10% solution of soda ash in water.

Products

Share

- Сomments

Loading comments...

Category

It's interesting