Blog

Over the years of development of Zladinox technology, serial production of both carbon and weather-resistant Damascus steels, as well as compositions based on titanium, zirconium and copper alloys has been established.

For the designation of Zladinox compositions, the A&R Company uses a developed symbolism consisting of the first letters of the name and numbers indicating the average content of carbon and alloying elements. For example, a weather-resistant composition of 95Х18 and 40X10С2М steels has the designation ZDI-1016 (Zlatoust+Damast+Inoxidable with an average carbon content of 1.0% and an average content of alloying elements (chromium, molybdenum, vanadium, etc.) - 16%). Table 1 shows the chemical composition of the steels included in The most common Zladinox compositions.

Table 1. Chemical composition of weather-resistant Zladinox compositions

*ZDI-0225 – carbon-free non-filling composition used for the production of decorative elements

In addition to weather-resistant compositions, Zladinox also produces carbon compositions. In this case, the blade is marked with the letter ZD (Zlatoust+Damast) and numbers that also indicate the average content of carbon and alloying elements. For example, a composition based on u10a and 50HNM steels is designated ZD-0801 (table 2).

Table 2. Chemical composition of high-carbon compositions of Zladinox

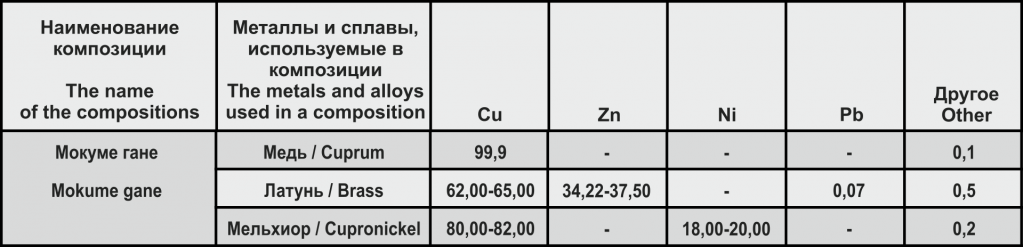

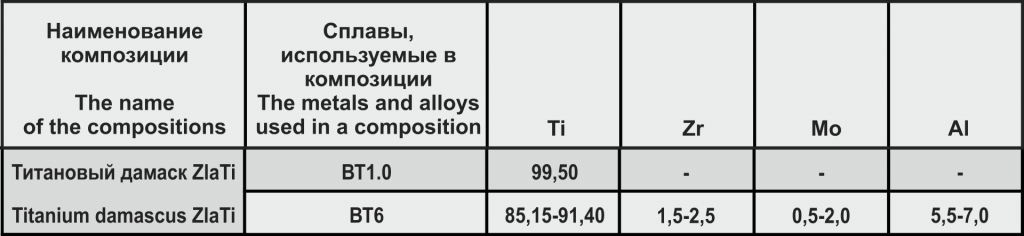

In addition to carbon and weather-resistant Damascus steels, Zladinox has established serial production of compositions based on titanium and copper alloys.

Table 3. Chemical composition of mokume gane

Table 4. Chemical composition of ZlaTi titanium Damascus

- Сomments